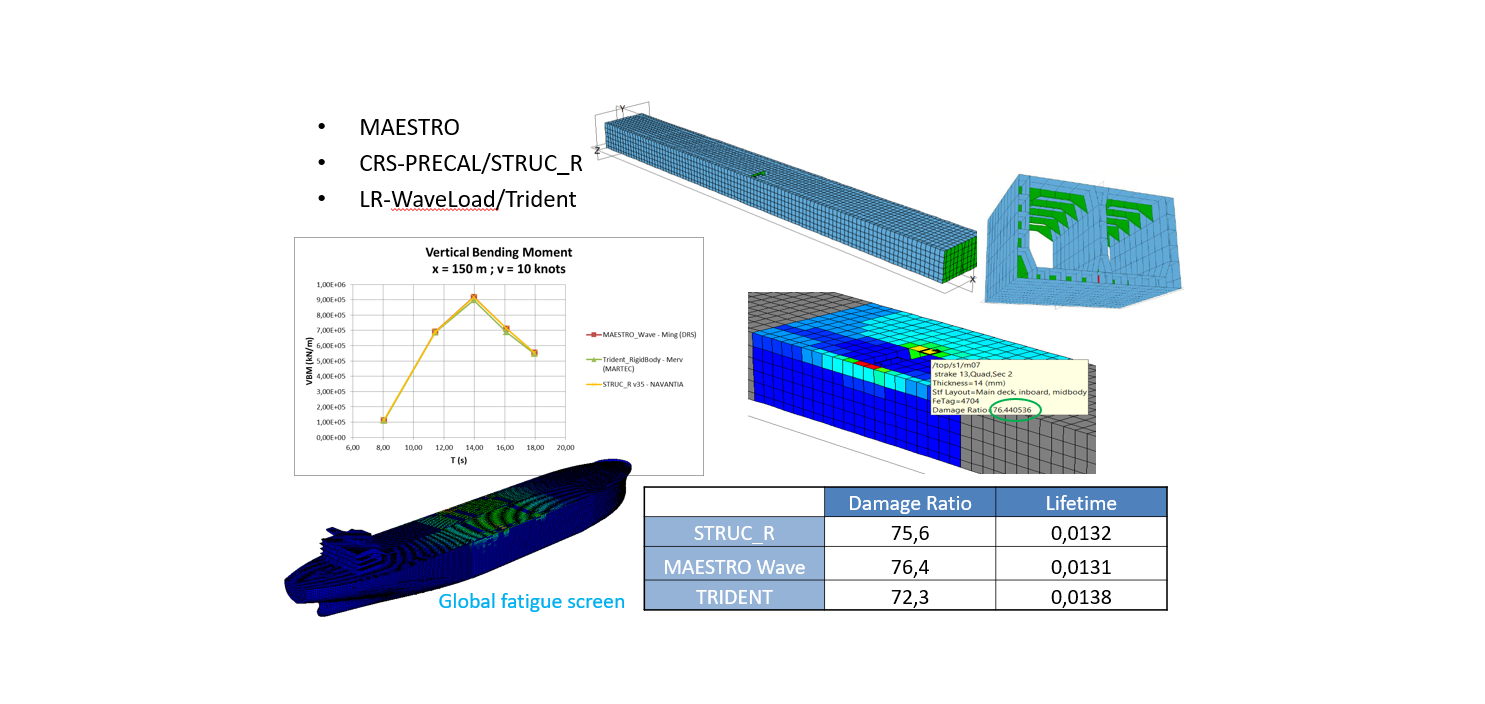

MAESTRO

Base Module

-

MAESTRO’s modeling paradigm is organized to rapidly generate a finite element model of an entire ship. Using high-level building blocks (i.e., MAESTRO substructures and modules), MAESTRO can leverage longitudinal uniformity typically found within portions of a ship (e.g., plating thickness or frame size throughout a cargo hold, etc.). Each module has its own local coordinate system, and can be copied, rotated or transformed. This paradigm not only supports the rapid creation of the finite element model but also the modification of the finite element model, which is routinely required during the design process. Hull girder properties such as inertias, cross-sectional area, neutral axis, and section modulus can be plotted and queried for any section cut within the model.

In addition to its built-in modeling capabilities, MAESTRO can read geometry from FEMAP, Nastran, NAPA Steel, DXF, and polygon mesh (.ply) files. Once a model is loaded into MAESTRO from another source, all of the hull girder properties, ship-based loading, post-processing, and advanced capabilities are available to the user just as if the model had been created in MAESTRO.

MAESTRO also provides fine meshing capabilities which allow the global model to be automatically refined while maintaining the original scantling properties and loads. The fine mesh model(s) can be analyzed as a separate model or integrated into the global model. Either option automatically applies the appropriate boundary conditions to impose the global loads onto the fine mesh model(s).

-

MAESTRO offers numerous ship-based loading patterns (e.g., Basic Loads: Cargo Loads, Liquid Tank Loads; Sea Environment: Hull Girder Loads/Sea Loads/Ship Motion Loads; and Operational Loads: Slamming/Flooding/Docking) to accurately and efficiently produce the necessary load cases. These load patterns include scaled masses, panel pressures, mass distributions, tank loads, longitudinal and transverse hull girder load distributions, hydrostatic loads (stillwater/wave), additional accelerations, and hydrodynamic loads.

Tanks are easily modeled and loaded in MAESTRO similar to hydrostatic analysis tools by leveraging the existing structural model to define the tank boundaries. Loads can be specified by a discrete mass or percent filled. MAESTRO creates the appropriate loads based on the user-defined density and permeability and automatically manages the element pressure side, even for elements shared between tank boundaries. Tank loads can be varied between load cases allowing the user to create multiple conditions within a single model. For each load case, a tank table is available summarizing the tank volumes, loads, and centers of gravity.

MAESTRO also includes a load balance capability which automatically balances the model in a stillwater or wave condition for each load case. Once a model is loaded and balanced, multiple longitudinal and transverse distributions (e.g., weight, buoyancy, shear force, bending moment, etc.) are available to quickly QA the model before solving.

-

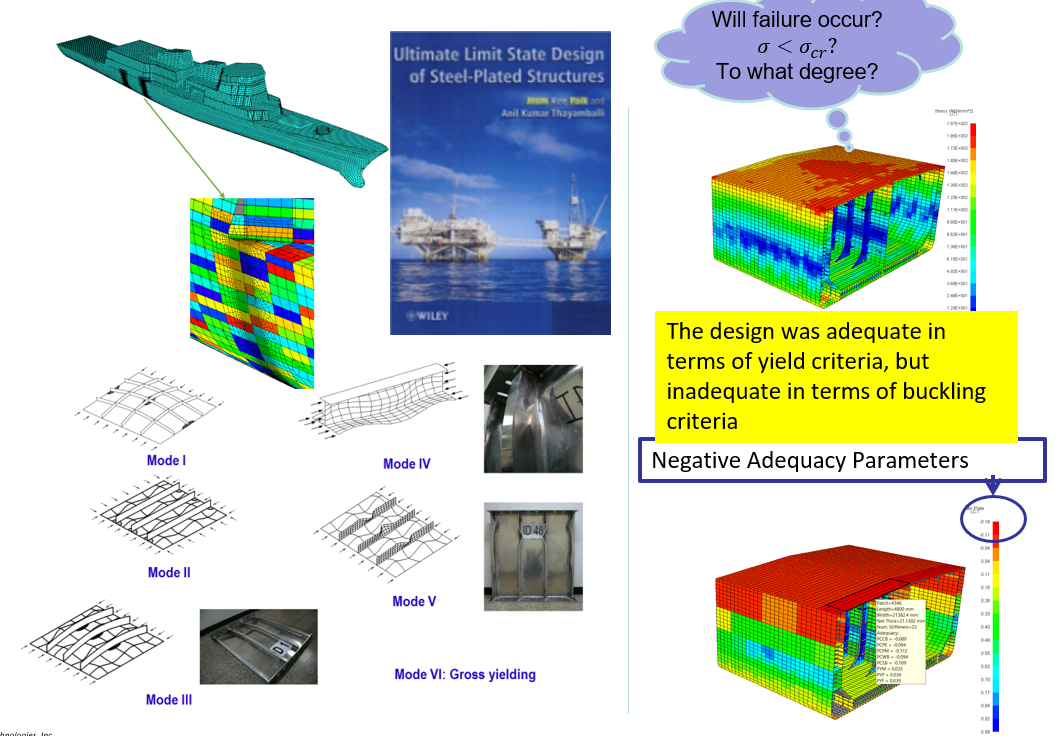

In addition to calculating displacements and stresses using the finite element analysis method, MAESTRO also performs an automatic failure evaluation of the principal structural members. Core to the modeling paradigm in MAESTRO is the ability to retain critical stiffened panel boundary conditions and parameters (e.g., true panel spans) for proper and accurate buckling assessment downstream in the analysis process. This automatic stiffened panel search capability can be performed on a MAESTRO model, imported fine mesh model, or combination of coarse mesh and embedded fine mesh. The principal structural members of the global model typically include all of the stiffened panels and their associated beams, transverse frame segments and longitudinal girders. These failure evaluation modes address yielding, buckling, and other major failure modes typically found in design criteria.

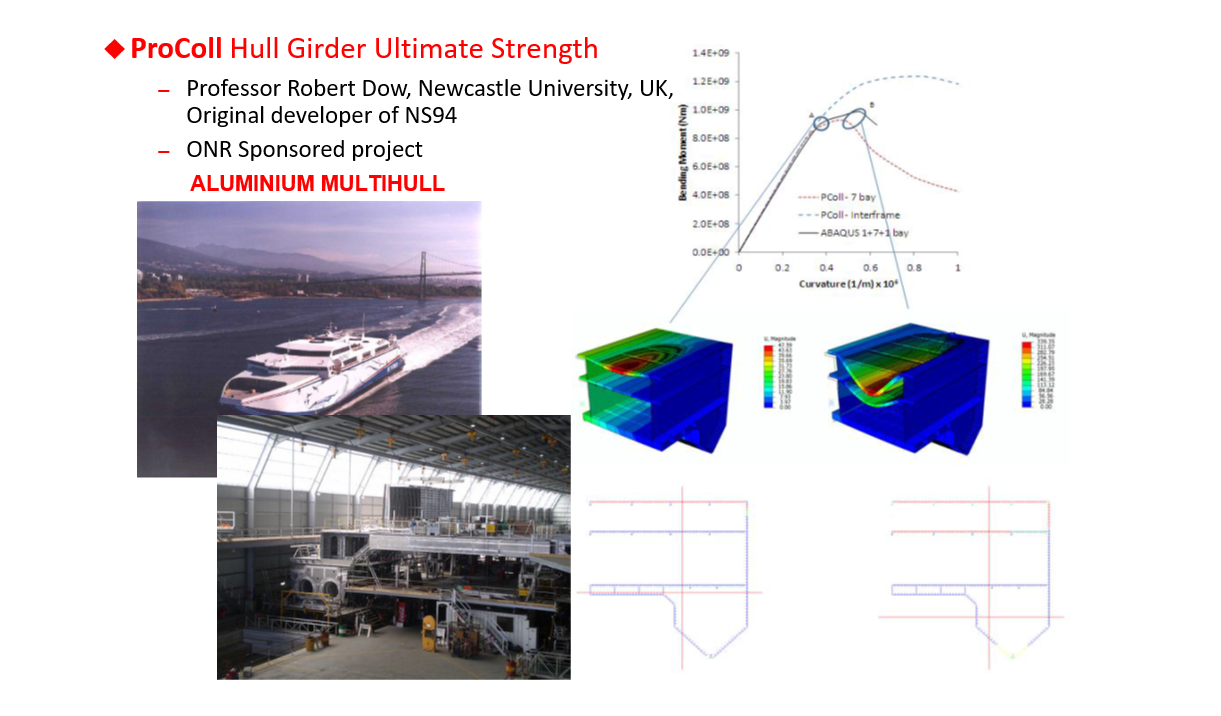

For each load case that is being analyzed, the failure analysis provides a quantified evaluation of the failure modes for each principal structural member. This is one of the most powerful failure evaluation capabilities available to the ship structural engineer, and results in a comprehensive level of information that identifies structural problems associated with events such as buckling. These structural failure evaluations are used by the structural engineer to assess the adequacy or degree of conservatism that is represented by the design. The available structural evaluation methodologies include MAESTRO Evaluation, ALPS/ULSAP, ALPS/HULL (hull girder ultimate strength), ABS High Speed Naval Craft (HSNC) and Offshore Buckling Guide, and US Navy NVR criteria.

A structural evaluation framework in MAESTRO exists so that additional design criteria and class rule checks can be easily implemented as needed. The stiffened panel parameter and load generation capability is modularized so that it can be leveraged with multiple rule sets.

Ships analyzed with MAESTRO

Additional Modules